The spindle is one of the most important components in advanced manufacturing, where precision and reliability can’t be compromised. The machining spindle, regardless of whether it is used to sculpt high-quality aerospace alloys or fine-tune components for medical devices with high tolerance, is the secret force behind accuracy and speed.

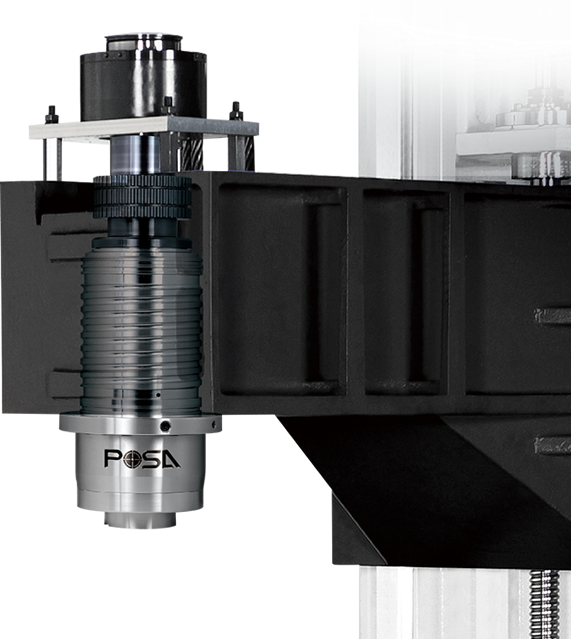

At the forefront of this specialized industry are elite spindle manufacturers like POSA Machinery, who are redefining what performance and durability look like in industrial machining environments.

Image credit: posa-spindle.com

The reason the Spindle Is the Heart of the Machine

Spindle quality is the determining quality of every CNC machine. Imagine the spindle as the heart of any CNC lathe or machining centre. It is the engine that drives the cutting tool with great precision, stability, and torque. A badly designed or incorrectly aligned spindle isn’t only the result of damaged parts. It can also cause damage to the machine, decrease time-to-market, and shut off the entire production process.

This is where the precision spindle technology is what makes the difference. Precision spindles, in contrast to standard parts, are designed, checked and calibrated with great care to meet the needs of extreme and high-demand conditions.

POSA Machinery: More Than Just a Spindle Manufacturer

While many spindle companies claim to offer high precision but few have the wealth of the experience and expertise that POSA Machinery has acquired over a long period of time. They are known for their strict internal testing procedures and commitment to international quality standards. POSA does not just produce spindles they craft performance-driven solutions tailored to meet the various requirements of today’s industries.

POSA spindles are found in a variety of machines, ranging from horizontal and vertical machining centers to tool grinding machines. The spindles are backed with a meticulous R&D process that is focused on functionality, but also durability over the long term, vibration control and thermal stabilty.

The Evolution of the CNC Lathe Spindle

The CNC lathe spindle has undergone remarkable innovation in recent years. Not just a rotational axis, today’s spindles integrate sensors cooling systems, sensors, and sophisticated balancing systems. POSA CNC lathe spindles allow the machinists with flexibility when handling hard and soft metals, without compromising the precision. By incorporating advanced ceramic bearings, as well as premium steel, these spindles cut down on thermal expansion while maintaining tight tolerances even during extended runs. This level of reliability leads to improved quality of the part as well as reduced downtime and improved tolerances.

Customized Machining Spindles for Machining that Meet the Real-World Demands

There’s no universally-fit-all spinning machine, particularly in the fields of mold and die manufacturing, automotive, aerospace. POSA is aware that each application will have its own set of requirements. This can be related to spindle speed, load capacity or environmental resistance. So, they offer flexible spindle configurations based on particular client requirements. When it comes to designing a spindle for vertical milling operations or adding a high-frequency spindle to the compact structure of a system, POSA provides the flexibility and engineering assistance that modern manufacturers need.

More Than Machines: A Commitment to Craftsmanship

What is what sets POSA apart isn’t its range of spindles it’s the underlying philosophy behind the spindles. The company is a believer in the fusion of creativity and craftmanship. The designers work closely with their customers, listen to pain points and continually adapt their offerings to remain ahead of the ever-changing market requirements. In a time where machine uptime, accuracy, and consistency can decide the fate of the production line, choosing the right spindle partner is everything.

Final Thoughts

The future of manufacturing isn’t just about faster machines, but also more intelligent and more reliable parts. POSA Machinery is an example of what world-class spindle manufacturers can achieve when they combine technical mastery with a customer-first mindset. It doesn’t matter if you require a powerful CNC lathe spindle, a heavy-duty machining spindle, or a precisely tuned precision spindle, deciding on the right spindle doesn’t only matter about the details, it’s an important decision that affects everything that follows.